- Mon-Thurs 9am – 5pm | Fri 9am – 3pm

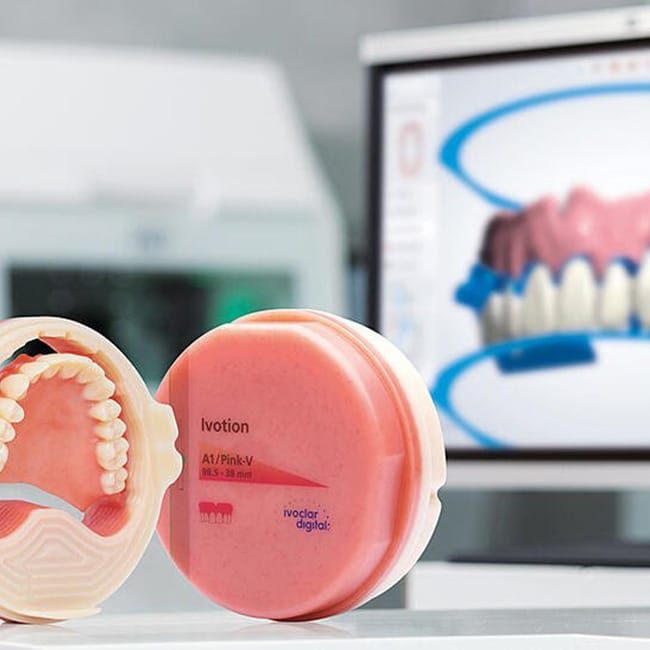

Digital dentures are a new, innovative concept in denture design and manufacturing. At Digital Denture Centre, we use 3Shape CAD/CAM software and a state-of-the-art PM7 Ivoclar 5-axis milling machine to create full, partial and immediate digital dentures. This computer-aided process allows us to produce perfectly fitted dentures that look natural and feel comfortable.

Digital dentures are quickly becoming the new standard for denture technology—and for good reason. If you’re considering getting new dentures, we invite you to come and experience the difference at our clinic in Bendigo. To find out more or book an appointment, please call us on 03 5454 3997.

There are many benefits to choosing digital dentures, including:

More accurate & precise fit: While traditional or ‘analogue’ dentures are handmade by a denture technician, digital denture impressions are scanned straight into digital form. The Ivoclar PM7 mill mills the denture out of a PMMA disc, resulting in a more accurate and precise fit.

Increased comfort: With a better fit comes increased comfort—digital dentures are less likely to shrink during the plaster casting or acrylic curing process, meaning they’ll fit more snugly and comfortably in your mouth. No more slipping or moving around!

Fewer appointments: Using the BPS system, we can combine your second and third appointment into one. This means less time spent in the dental chair and fewer trips to the clinic. Another option is using a reference denture, which would allow us to go from the impression process straight to a hard try-in, eliminating the need for registration appointments.

Fewer adjustments: With the precision of digital dentures, there is less need for adjustments and relines. However, please note that dentures may require occasional adjustments if there are any sharp bits of bone, thin oral mucosa, or other issues that need to be addressed.

We use the latest CAD/CAM software and equipment to design and manufacture our digital dentures. No guesswork required—this computer-aided process allows us to place the teeth exactly where they naturally occur in your mouth, ensuring a comfortable and aesthetically pleasing result.

The software also allows us to make changes to the denture design quickly and easily, so we can be sure that you’re getting exactly what you need. And because the entire process is recorded digitally, we can replicate your denture exactly if you ever lose or damage it.

Our dental prosthetists are fully trained in SEMCD (scanning, evaluation, manufacture and clinical delivery) of digital dentures, so you can rest assured that you’re in good hands. To find out more about our digital denture technology, please get in touch.

Digital dentures are a type of denture that is made using computer-aided design and manufacturing technology. They are a new and innovative way to create dentures and are designed to provide a more comfortable and natural fit.

Traditional dentures are made by hand, while digital dentures are made using computer-aided design and manufacturing technology. This means that digital dentures can be made to precise specifications and are often more comfortable and natural-looking than traditional dentures.

First, an impression or scan of the mouth is taken. This is used to create a 3D model of the teeth and gums. The denture is then designed on a computer using special software. Once the design is complete, it is sent to a milling machine which will carve the denture out of PMMA material.

Digital dentures are made from a high-quality PMMA material that is eight times harder than conventional dentures. This makes digital dentures much more durable and long-lasting than their traditional counterparts.

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

9am – 5pm

9am – 5pm

9am – 5pm

9am – 5pm

9am – 3pm

Closed

Closed

ABN 74 156 635 031